If you’re planning on having a dust extraction system installed, there are several different parts that you may need. Dust extraction systems are more than just pieces of pipe, vents, and extractors.

The following list will give you a better idea of the many products that are used by a dust extraction company during the dust extraction installation process in one way or another.

Contents

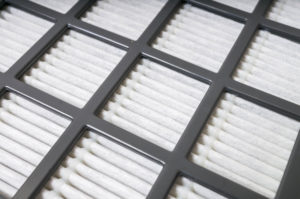

Air Filters

Air filters are used to filter dust particles out of the air flowing into the system. If you’re looking for an air filter, you’ll need to consider the type of unit you have. Hence, suitable replacement media is needed. The following are some of the most common filters available:

- Multi-pocket filter – removes airborne particles

- Synthetic multi-pocket filter bags – made from specially designed microfibers

- Panel filters – disposable filters that are suited for air conditioning and venting systems

- Mesh grease filters – created for commercial kitchens to reduce the grease that travels into the extraction system. An alternative to this is the stainless steel baffle filter

- Cartridge filters – can be used in different settings, and they save up to 40% space when compared to others

Automatic Extraction

Automatic extraction systems remove airborne particles from any environment since common processes can produce a ton of fumes and dust. Hence, automatic extraction systems need LEV testing to keep everyone in your workplace safe.

Controllers

Controllers can be used to offer flexibility. With the push of a button, they work to provide optimal performance for your extraction unit. All operations of the system can be programmed to be integrated with controllers.

Controllers can be used to offer flexibility. With the push of a button, they work to provide optimal performance for your extraction unit. All operations of the system can be programmed to be integrated with controllers.

Sensors

Sensors can be used to monitor if a machine is on or off, pressure levels, or dust levels. When triggered, sensors can produce high and low alarm signals.

Bins

Dust extractor/collector bins come in a variety of different sizes and collect dust.

Blow Off Units

Blow off units are connected to the system. They alert the user if things are not running how they should while pressure is being released.

Clips

If you’re planning to install any ductwork, clips are a must-have. These are useful for connecting ducting accessories to flexible ducts, and they provide a secure grip. Your hard work will never be able to disconnect because of high pressure or mishaps ever again.

Cloaking Plates

Cloaking plates are made from high quality galvanised steel, and they’re used for keeping the holes in the walls very tidy at ducting sites. Cloaking plates are available in a range of different sizes to suit just about any size.

Dampers

Dampers are useful at your mounting points. They are also essential for keeping a quiet workplace since they can easily isolate noise from the rush of air in the system. Additionally, they can also reduce the vibration from the air stream, and they reduce the effects of wear and tear due to system vibration.

Diaphragm Valves

Diaphragm valves are specially designed valves that are on-off throttle valves, and they’re used to control the amount of air flowing through the system. This is done by changing the speed and the velocity as needed. Its name comes from the fact that it is a thin membrane that controls the valves’ closing and opening.

Ducting Fittings

Brackets

These can be mounted as needed on the floors, walls, or even on the ducting material. They’re useful for providing support for fixtures and keeping them in place.

These can be mounted as needed on the floors, walls, or even on the ducting material. They’re useful for providing support for fixtures and keeping them in place.

Fixtures

These can be a range of differently shaped pieces that are required for ducting work. Some are elbows, connectors, dampers, duct Y pieces, and reducers. All of these can be sized according to the system.

Roof Flashing

Flashings can come in either aluminium or rubber, and they’re specially designed for slate roofs. These provide a clear indicator of where your designated pieces of pipe will fit and eliminate the guessing phase out from your work. Roof flashing also reduces the need for cutting.

Duct Tape

Duct tape is used on your ductwork as a means of providing an airtight seal. The seal is not only long-lasting, but it also creates a barrier around your ducts.

Duct tape is excellent for creating a moisture-proof seal around the work as it remains free from dust and other contaminants. The material used in its construction is aluminium foil, while there’s another side made of pressure-sensitive adhesive.

Duct Wrap

Duct wrap is a glass wool insulated wrap used for both acoustic and thermal insulation of HVAC applications. The wrap is usually made to suit different sized applications and is made of glass wool with reinforced aluminum foil

Dust Extractor

A dust extractor improves the air quality when working in an environment with dust and gives you with a clean and safe workplace.

Dust extractors differ depending on the number of filter bags that come with the extractor. Extractors can have multiple bags to collect the dust and particles that are filtered from within the area.

They are usually fitted with heavy-duty fans, and they can be used in schools, colleges, or other smaller workshops, depending on the size of the extractor. Unlike other solutions, these are typically the most cost-effective solutions.

Dust Hoods

Hoods come in an array of sizes and shapes, and they’re used to remove additional dust from areas prone to having more dust. These hoods are typically used in industries such as woodworking and others with higher concentrations of dust in the atmosphere.

Extractor Bags

Extractor bags are used on extraction filters. However, each filter works with a different size or type of bag. Extractor bags are used to store particles collected by the extractor and are available in varying lengths and diameters.

Fans

Fans provide that breath of fresh air for any facility as it extracts dust and fumes. While the ductwork offers the means for air to flow, fans usually transport the poor quality air out of the room. Fans are made from a variety of materials to suit their working environment.

Flexible Ducting

Just like many other products, flexible ducting also comes in a series of different materials. However, the most common is made from aluminium foil. These flexible tubes are used to either extract or supply during the ducting process. Since it is constructed from laminated polyester, aluminium, and high tensile steel, the ducting is fire resistant.

Just like many other products, flexible ducting also comes in a series of different materials. However, the most common is made from aluminium foil. These flexible tubes are used to either extract or supply during the ducting process. Since it is constructed from laminated polyester, aluminium, and high tensile steel, the ducting is fire resistant.

Flexible Extraction Arms

Flexible extraction arms are well suited for extracting the likes of dust, fumes, and even solvents. The arm consists of a parallelogram on the inside that is supported by a spring. The hose is coated with a special PVC coating, and the internal wires a spiralled steel. Due to its design, the arm can swivel in just about any direction that you require.

Grilles

Grilles can be designed and used as either extraction or supply points. They’re typically used in ceilings, walls, or even directly onto your ductwork. They usually have movable blades that are set to 90 degrees that allow proper directional adjustment. However, adjustments can be easily made by hand as you turn the blades.

Hose Clamps

Clamps are used to quickly connect equipment such as filters, fans, and others to ducts. Due to the design, they can also efficiently prevent vibration from being transmitted through the ducting system.

Hoses

Hoses are made to be flexible, and they’re manufactured from special materials. These materials can be coated in glass fabric, as well as reinforced in steel wires. They’re also known to be temperature resistant, robust, and highly flexible. Hoses are used for the extraction and the supply of clean air into workspaces.

Kits

Ducting kits can come with their own unique features. Some are used for doing repairs, while others are used for replacing parts and pieces of machinery. The kit you purchase can contain just about everything that you need for your system.

Louvres

Louvres can be either circular or square, and they’re typically made from aluminium. These products are used for the intake vents and supplying the system with air. They can also be used as exhaust vents at the end of the system.

Mobile Dust Extractors

Mobile extractors are used for various extraction applications, and they can be moved outside of the typical working range. As the extractor works, users are notified when the filter has almost reached its capacity. Mobile extractors are usually built to the highest industry standards.

Mobile extractors are used for various extraction applications, and they can be moved outside of the typical working range. As the extractor works, users are notified when the filter has almost reached its capacity. Mobile extractors are usually built to the highest industry standards.

PPE

Personal protective equipment is used to protect those who are wearing them. PPE can include gloves, helmets, face shields, steel toe boots, protective clothing, and many other pieces of equipment. When used, PPE is guaranteed to offer extra protection if safety equipment fails.

Pressure Gauges

Pressure gauges are suited for measuring the condition of extraction filters. In the case where the pressure is too low, your system might not be properly filtering. If it’s too high, damages can be done to the system. Pressure gauges allow you to monitor and keep the pressure between a specific range.

Sealant

A sealant is used to ensure that air isn’t leaking from your system. Sealant can be used in either low or high-pressure situations, and it’s excellent for use in confined settings.

Spray Booths

Spray booths are enclosures that are used to filter or extract any vapours that are created during various processes. Processes such as finishing, painting, and even coating can produce a lot of fumes. Hence, spray booths are necessary to prevent the fumes from spreading as it filters and keeps everyone safe.

Conclusion

Dust extraction and ducting systems are made up of various small and large components. If ever something goes wrong, several different components may need replacing or servicing. So, if you ever experience problems with your system, be sure to contact us. We are also written a guide to dust extraction.